צבע אדום מורכב ממרכיבים וכימיקלים שונים. אותו הדבר נכון לגבי עיצוב ממשק משתמש וחוויית משתמש. מקלדת אדומה על מקבוק עשויה מחומרים שונים, בעוד שצבע שקית התה הוא תוצר של חומרים והרכבם הכימי. באופן דומה, צבע אדום על מכונית עשוי מרכיבים שונים, כולל הצורה והחומר של המפתחות. חשוב להכיר בכך שישנם סוגים רבים של רכיבים המרכיבים את UI ו-UX.

למה UI טוב זה חשוב?

לא ניתן להפריז בחשיבות עיצוב ממשק המשתמש (UI). אנשים שופטים מהר, והם לא אוהבים אתרים מסובכים לניווט. אם קשה להשתמש באתר או שאינו נותן את התוצאות הרצויות, סביר להניח שהמשתמש יעזוב ויחפש במקום אחר. הדרך הטובה ביותר לקבל ממשק משתמש של אתר לעבוד עבור העסק שלך הוא לעצב אותו עם הלקוחות שלך בראש. אם קל לנווט את המשתמש שלך, זה יגדיל את התנועה והמכירות.

ארגון טוב צריך לתת למשתמשים תחושה של שליטה וחופש. זה עוזר להם להרגיש בנוח להשתמש במוצר ומאפשר להם ללמוד מהר ולשלוט. המשתמש צריך להיות מסוגל לחזור בו במהירות אם משהו לא עובד כמו שצריך. הדבר מאפשר להם לבחון אפשרויות לא מוכרות מבלי לחשוש לטעות. אם המשתמש מרגיש מאוים מהחוויה, הוא יקח יותר זמן ויהיה זהיר יותר.

משתמשים לא אוהבים הפתעות. זה לא עוזר שיש אפליקציה שלפתע משנה התנהגות או מציגה תכונות לא מוכרות. משתמש יכול להיות מתוסכל ולהפסיק לאחר שניסה מספר פעמים להגיע לכפתור הנכון. UI טוב עושה את זה קל למשתמשים לעשות את הבחירה הנכונה ולהימנע מתסכול אותם על ידי הכרחת אותם שוב ושוב להקיש על הכפתור הלא נכון. שימוש עקבי בהתנהגות ימנע מהמשתמשים לאבד אמון באפליקציה, ויאפשר לה להיות יעילה יותר.

מי מעצב את ה-UI?

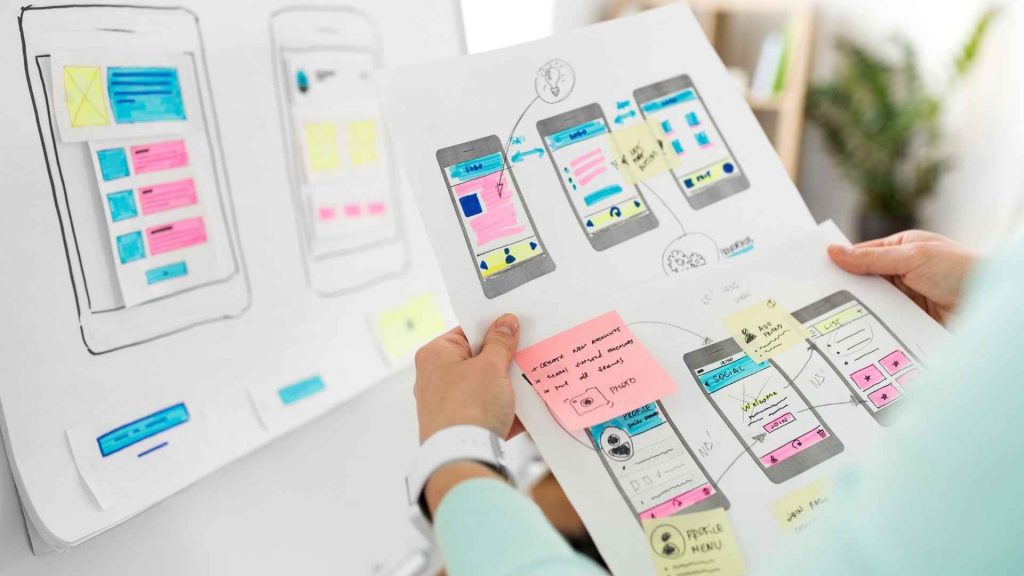

מי מעצב את ה-UI? השאלה הנפוצה ביותר שיש לאנשים בראש היא, ”מי מפתח את האפליקציה?” התשובה לשאלה זו תלויה במוצר ובקהל. חוויית המשתמש היא המפתח ליצירת מוצר מוצלח, ומעצב UI טוב ישקול את הצרכים וההעדפות של המשתמשים בעת קבלת החלטות עיצוב. בעוד שחוויית המשתמש חשובה, מעצבי UI חייבים לקחת בחשבון גם שימושיות ונגישות, כמו גם עקרונות עיצוב בסיסיים, על מנת ליצור מוצר נהדר. מעצב UI צריך ללמוד התנהגות משתמש וחוויית משתמש כדי לעזור להם לעצב חוויה אינטואיטיבית. בחירת הגופנים, סגנונות התפריט, כפתורים, סמלים ואלמנטים עיצוביים אחרים צריכה להיות מבוססת על מחקר נתונים ומשתמש.

תפקידו של מעצב UI הוא ליצור את האלמנטים החזותיים של ממשק, שעוזרים למשתמשים לנווט מאזור אחד של היישום למשנהו. הדבר כולל פיתוח סטנדרטים של מותג, פתרונות גרפיים, סמלים וסמלים. בנוסף לכך, מעצב UI צריך לדעת פיתוח קדמי, מכיוון שהוא יכול לעזור להם בתהליך העיצוב. בנוסף, למעצב UI צריך להיות ידע בתורת הצבעים, כמו גם ניסיון בהתפתחות חזיתית.

מה ההבדל בין UI ל UX?

ממשק המשתמש וחוויית המשתמש הם שני מונחים המשמשים לעתים קרובות להחלפה. ממשק משתמש (באנגלית: User Interface) הוא מערכת של מסכים, עמודים ואלמנטים ויזואליים אחרים שמשתמשים בהם כדי ליצור אינטראקציה עם מוצר או שירות. חוויית משתמש, לעומת זאת, היא החוויה הכללית שיש לאדם עם מוצר או מערכת. המשתמשים לא תמיד מודעים להבדל בין שני המונחים, ולעתים קרובות הם מבלבלים ביניהם.

שני המונחים חשובים בעיצוב וחשובים להבנה. UI מתייחס למראה ולהרגשה של מערכת, בעוד UX מתייחס לדרך שבה מוצר עובד. מעצבי חוויית משתמש מתמקדים בציפיות ובבעיות שהמשתמשים מתמודדים איתן, בעוד שמעצבי UI מתמקדים בקביעת הציפיות הללו. הם מחפשים מידע שונה כדי לקבוע אילו מוצרים הם המוצלחים ביותר. ההבדל המרכזי בין שני המונחים עשוי להיות פשוט כמו איך אדם מנווט באתר אינטרנט.

כדוגמה מהירה להבדלים בין השניים, בואו נסתכל באתר ביקורת סרטים. בעוד שה-UI יכולים לעזור לאנשים למצוא סרטים שהם מעוניינים בהם, ה-UX לעתים קרובות לוקה בחסר. למשל, לאתרי ביקורות סרטים יש נתונים רק עבור פרסומים גדולים ולא עבור סרטי אינדי. קשה למצוא את הסרט הנכון לצפות בו אם החיפוש שלך רחב מדי.

לקישורים נוספים בתחום: